OEM/ODM Heater Ceramic Plate Suppliers - Thermal Storage Honeycomb Ceramic – Hualian

OEM/ODM Heater Ceramic Plate Suppliers - Thermal Storage Honeycomb Ceramic – Hualian Detail:

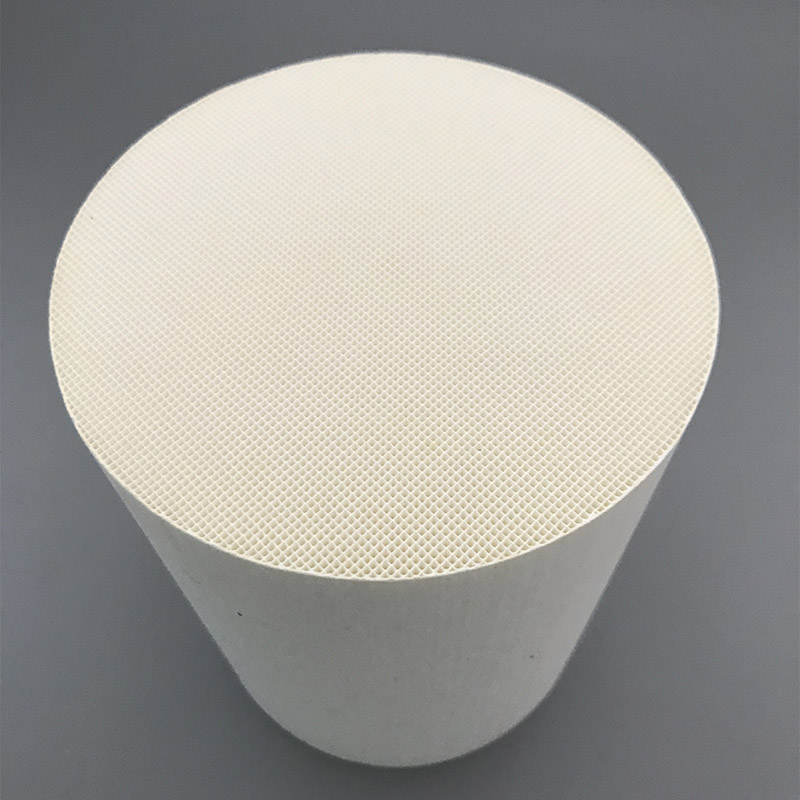

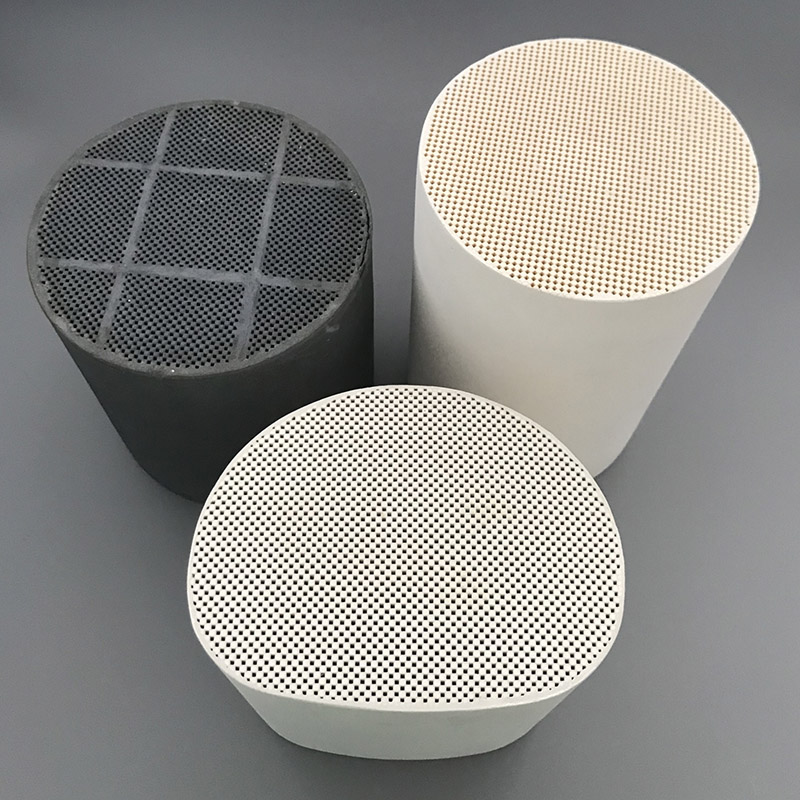

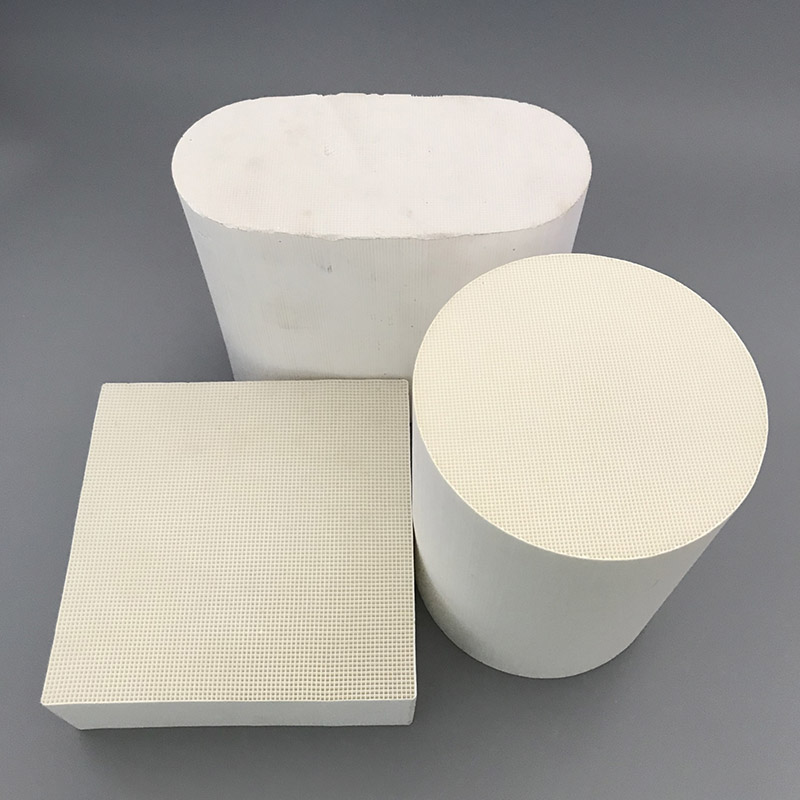

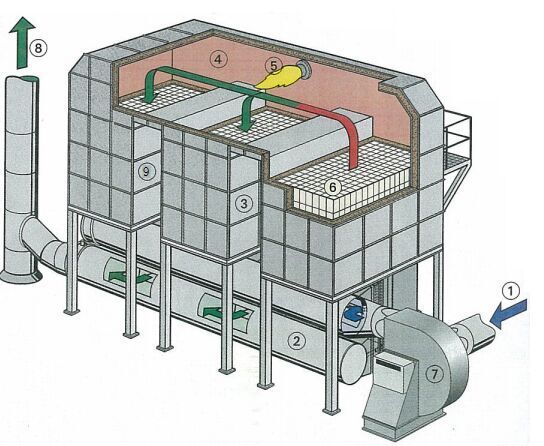

High Temperature Air Combustion (HTAC) is a new type combustion technology with enormous energy-conservation and environmental protection. The Thermal storage honeycomb ceramics are widely used in the various heating furnaces, hot blast furnaces, heat treatment furnace, cracking furnaces, roaster, melting furnace, soaking pit furnaces, oil gas boiler, etc in the steel, machinery, building materials, petrochemical, colored metal smelting and etc industries.

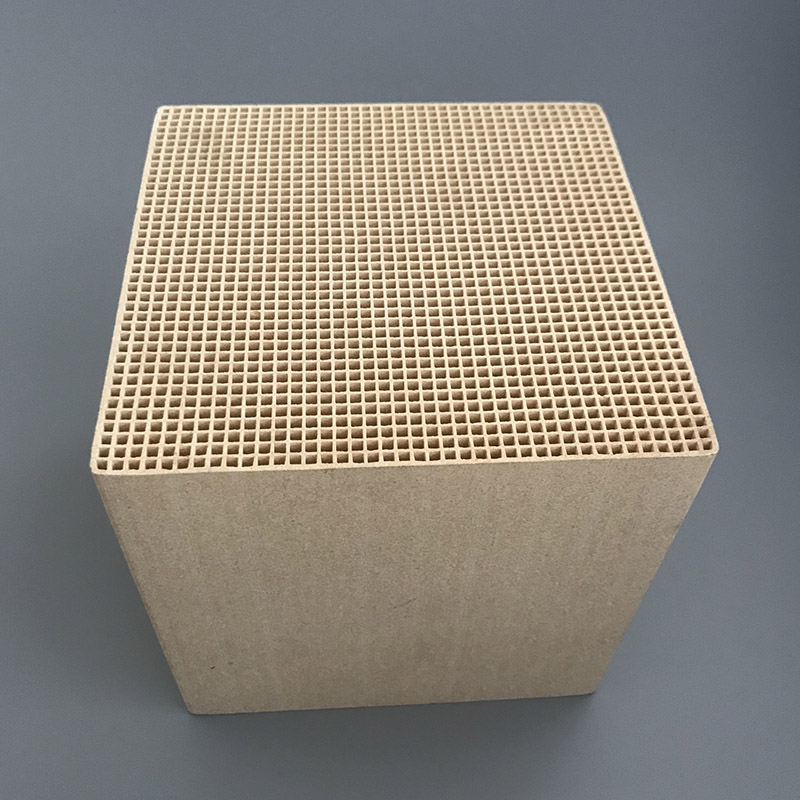

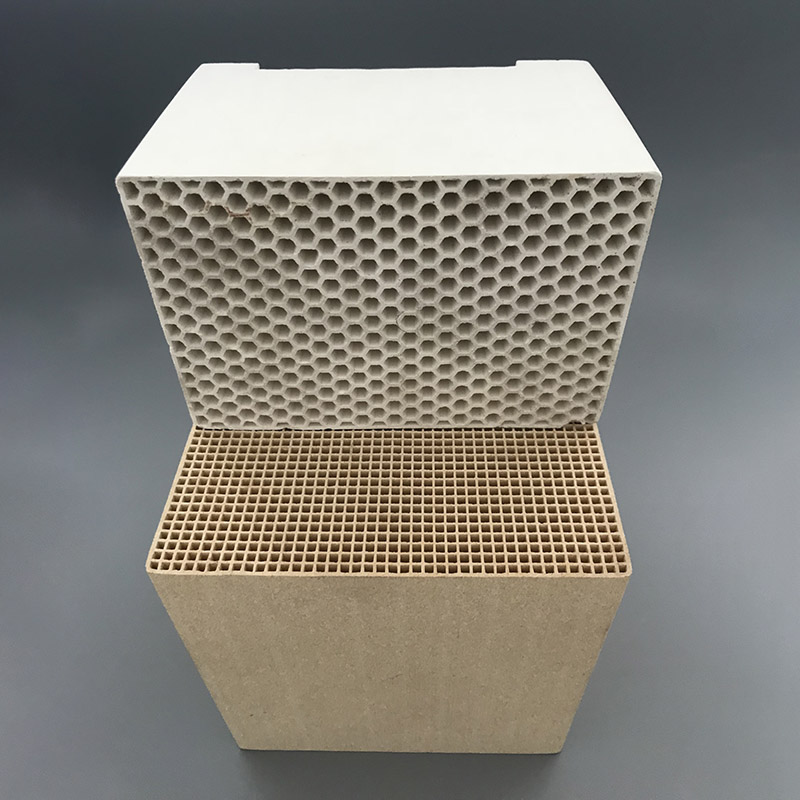

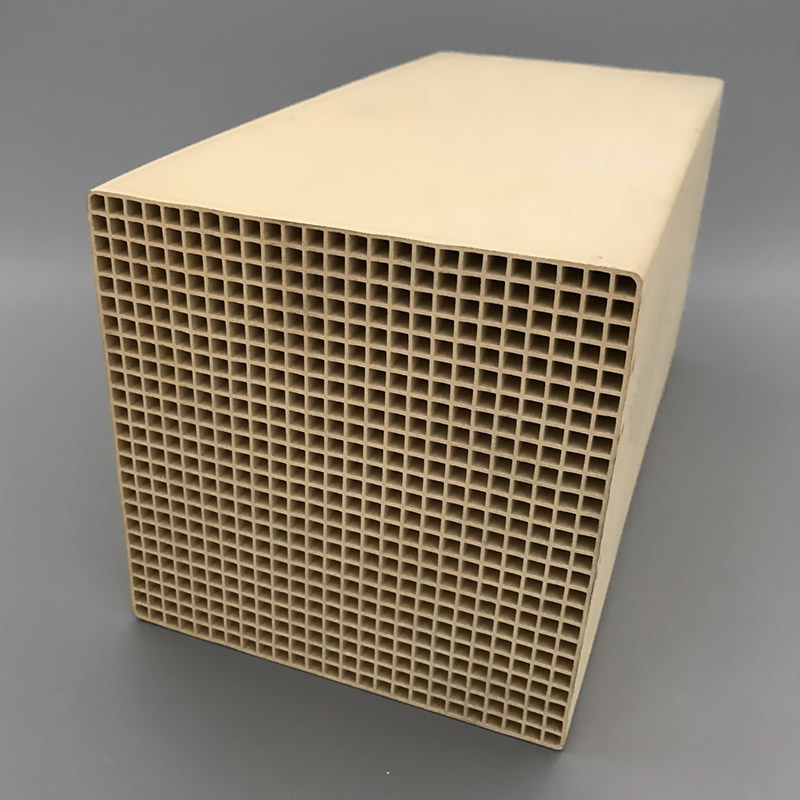

The corundum/mullite and cordierite/mullite complex thermal storage honeycomb ceramic developed by our company has the following notable characters: perfect high temperature resistance, anticorrosion, perfect thermal shock stability, high mechanical strength, large thermal storage capacity, advantaging heat conduction property, energy conserving result and service life are improved greatly. At present, our products have already been approved by numerous iron and steel enterprise and exported to Japan, South Korea and Europe and America market.

|

Index |

Metric Unit |

Value |

British Unit |

Value |

|

Material Density |

g/cm3 |

2.3-2.6 |

Lb/ft3 |

151 |

|

Average Linear Expansion (20-800) |

10-6/k-1 |

<2.5 |

||

|

Special Heat Capacity |

KJ/Kg |

900-1200 |

||

|

Heat Conductivity |

W/MK |

1.8-3.0 |

||

|

Maximum Application Temp. |

C |

1350 |

2450 |

|

|

Acid resist strength wt.loss |

% |

<4 |

||

|

Water Absorption |

% |

<5 |

|

(mm) |

Quantity of channels |

Wall thickness(mm) |

Channel Width(mm) |

Surface area(m2/m3) |

Void section (%) |

Packaging density(kg/m3) |

Weight per piece(kg) |

|

150*150*300 |

25*25 |

1.0 |

4.96 |

580 |

68 |

696 |

4.7 |

|

150*150*300 |

40*40 |

0.7 |

3.03 |

891 |

65 |

814 |

5.5 |

|

150*150*300 |

50*50 |

0.6 |

2.39 |

1090 |

63 |

903 |

6.1 |

|

150*150*300 |

60*60 |

0.5 |

1.99 |

1303 |

63 |

932 |

6.3 |

|

150*100*100 |

40*40 |

1 |

2.5 |

784 |

49 |

799 |

1.2 |

|

150*100*100 |

33*33 |

1.1 |

3.0 |

691 |

52 |

750 |

1.13 |

|

150*100*100 |

20*20 |

2.0 |

5.0 |

392 |

49 |

692 |

1.04 |

|

100*100*100 |

40*40 |

1.0 |

2.5 |

784 |

49 |

810 |

0.81 |

|

100*100*100 |

33*33 |

1.1 |

3.0 |

691 |

52 |

750 |

0.75 |

|

100*100*100 |

20*20 |

2.0 |

5.0 |

392 |

49 |

680 |

0.68 |

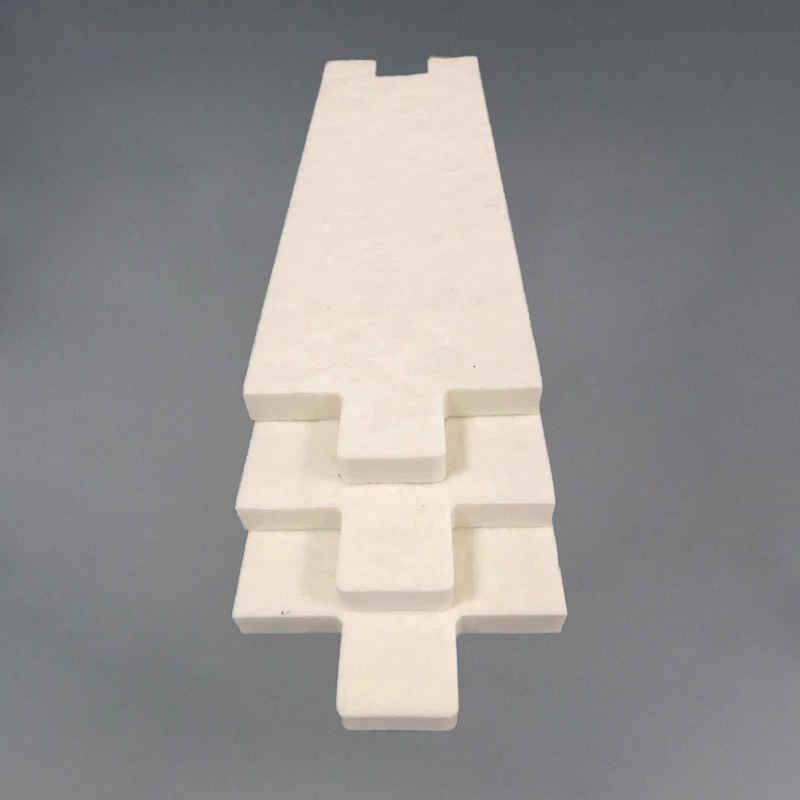

Product detail pictures:

Related Product Guide:

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for OEM/ODM Heater Ceramic Plate Suppliers - Thermal Storage Honeycomb Ceramic – Hualian , The product will supply to all over the world, such as: Brasilia , Lesotho , Manchester , With more and more Chinese products around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to offer you both better products and service, because we are more and more powerful, professional and experience in domestic and international.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.