China Cheap Catalyst Substrate Ceramic Manufacturers - Universal diesel particulate filter Euro IV catalytic converter – Hualian

China Cheap Catalyst Substrate Ceramic Manufacturers - Universal diesel particulate filter Euro IV catalytic converter – Hualian Detail:

1. Why is it called a partial flow particle trap? During operation, the engine exhaust enters the particle trap from the inlet, and most of the air flow flows through the filter medium. The particles are trapped on the surface of flat felt and corrugated felt, and react with NO2 at a certain temperature to eliminate the particles; Therefore, if the temperature reaches the conditions, the partial flow particle trap is not easy to cause blockage and is basically maintenance free; If the continuous exhaust temperature of warm tail gas reaches more than 250 degrees, preferably 350 degrees, and the original exhaust value is less than 2.0, the system regeneration is smooth; The carrier material is iron chromium aluminum material, which is temperature resistant and not fragile during disassembly and recoil.

2. Disadvantages: the filtration efficiency is not high, only about 50%; If the temperature fails to reach the conditions for a long time, POC will be blocked, which needs to be removed for maintenance.

Partial flow filter product introduction

1、 Partial flow particle trap SPF

1. Structure and working principle of SPF

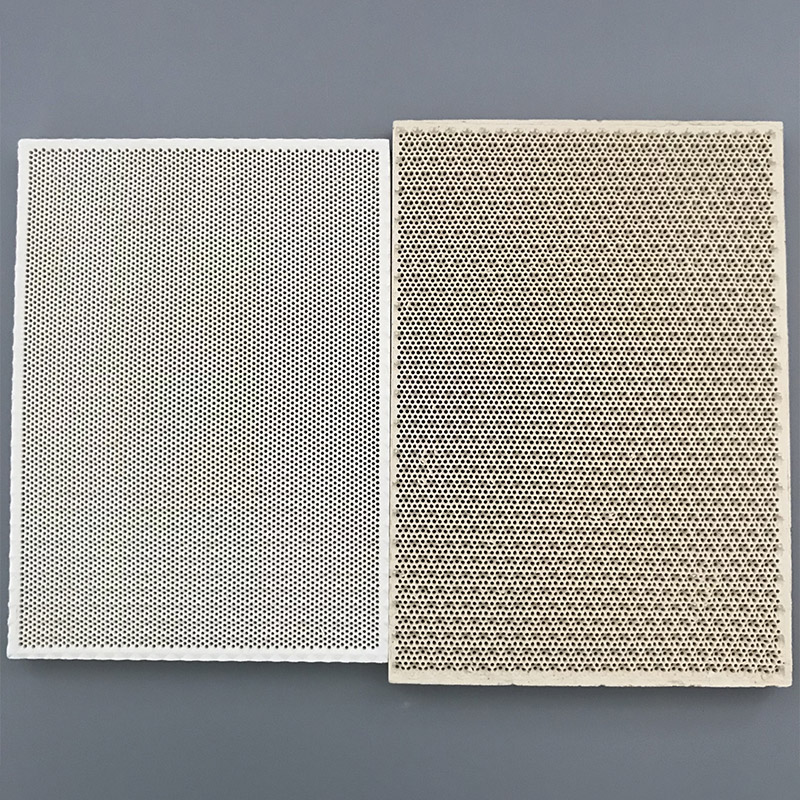

● it is made of high temperature resistant metal fiber sintered felt filter medium material;

● it is composed of alternating superposition of flat felt and corrugated felt. One end of corrugated felt is combined with one end of upper and lower flat felt to form a “zigzag” shape;

● the downstream end of the flat felt is provided with small holes at a certain distance, and the downstream end of the corrugated felt is pressed with a transverse groove perpendicular to the air flow channel;

● during operation, the engine exhaust enters the particle trap from the inlet, and most of the air flow flows through the filter medium. The particles are trapped on the surface of flat felt and corrugated felt, and react with NO2 at a certain temperature to eliminate the particles;

● part of the air flow is directly discharged through the small holes of the flat felt, thus forming a partial flow filtration function.

2. SPF structure diagram

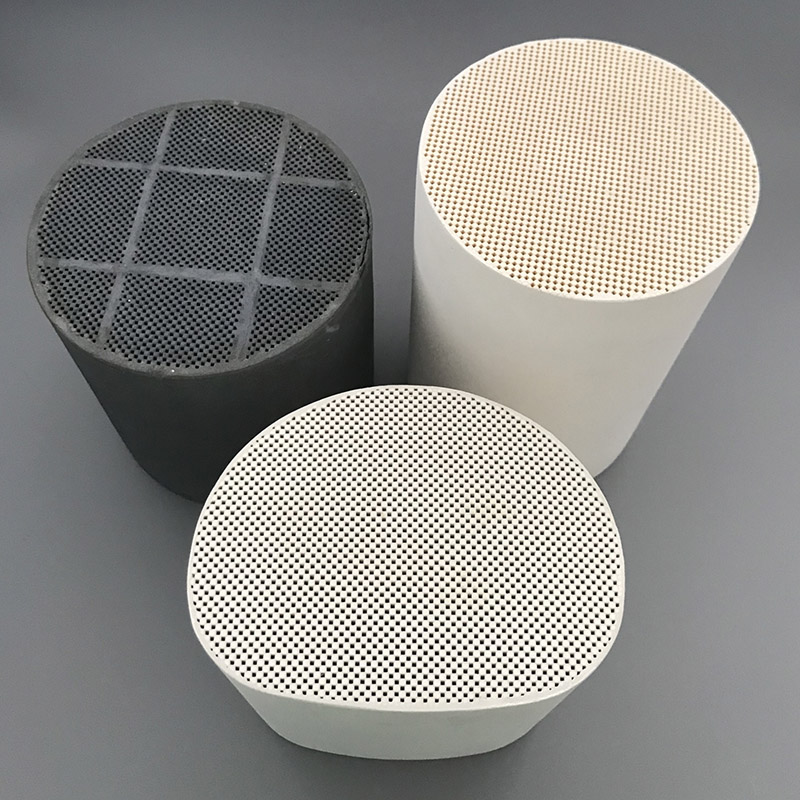

There are two main upgrading schemes for diesel engine tail gas post-treatment unit in China IV era. One is to treat nitrogen oxides in tail gas with urea solution by using selective catalytic reduction (SCR) technology; One is EGR (exhaust gas recirculation) technology that processes the particles produced by combustion through diesel particulate filter (DPF) or diesel oxidation catalyst (DOC). At present, DPF is recognized by the public as an effective way to reduce diesel engine PM. When the National IV standard is upgraded to the national V standard, PM will be the key problem to be solved. The solution is to use DPF.

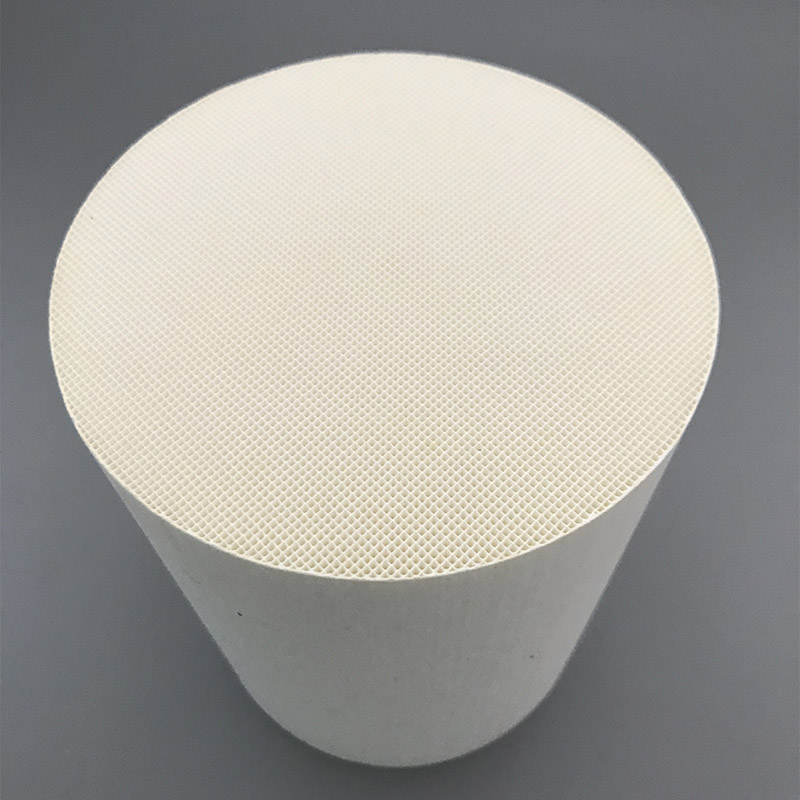

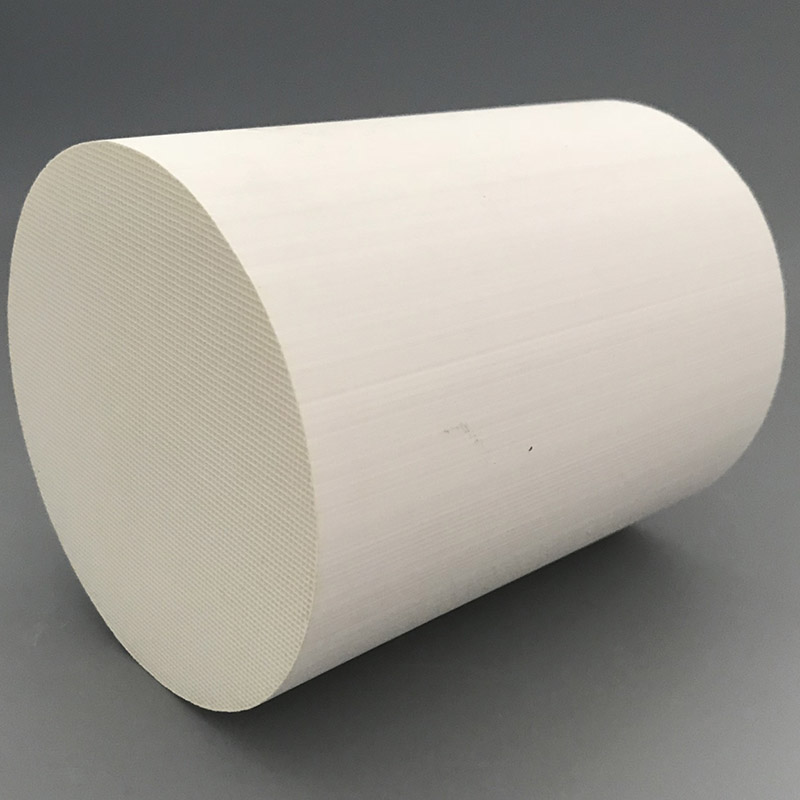

As shown in Figure 1, diesel particulate filter (DPF) is a device installed in the diesel vehicle exhaust system to reduce particulate matter (PM) in the exhaust through filtration. DPF captures particles through surface and internal mixing filter devices, such as diffusion precipitation, inertial precipitation or linear interception, which can effectively purify 70% ~ 90% of particles in exhaust. It is one of the most effective and direct methods to purify diesel engine particles, and has been commercialized internationally. In order to meet Euro VI or US 2010 emission regulations, the diesel engine exhaust after treatment system will be more complex. It is necessary to integrate diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and selective catalytic reducer (SCR) to control diesel engine emissions (Fig. 2).

Diesel particulate filter (DPF) mainly includes three working processes: particulate filter empty, particulate filter full and particulate filter reduction. When the particulate filter is empty (Fig. 3), because there is no particle blockage in the DPF, the exhaust gas flow resistance is very low, which will not affect the normal operation of the engine (such as fuel consumption, power), etc. With the continuous generation of soot particles, the soot particles captured in DPF gradually increase, resulting in the increase of exhaust resistance, and the fuel consumption and power of the engine are affected by the increase of exhaust back pressure. The engine control unit monitors the internal pressure of the DPF through the exhaust gas pressure sensor. When the engine control unit monitors that the internal pressure of the DPF reaches a certain value, the exhaust gas is difficult to be discharged, which greatly limits the power and fuel economy of the engine. At this time, the engine control unit controls the cleaning and reduction of soot particles by itself, The soot particles gathered in the DPF are burned at high temperature to realize the regeneration of DPF.

two Regeneration of diesel particulate filter (DPF)

Diesel particulate filter (DPF) has high filtration efficiency for soot particles, which can reach 60% ~ 90%. During filtration, the accumulation of particles in the particle filter will increase the exhaust back pressure of the diesel engine. When the exhaust back pressure reaches 16 kPa ~ 20 kPa, the performance of the diesel engine begins to deteriorate. Therefore, the particles must be removed regularly to restore the particle filter to its original working state, that is, regeneration.

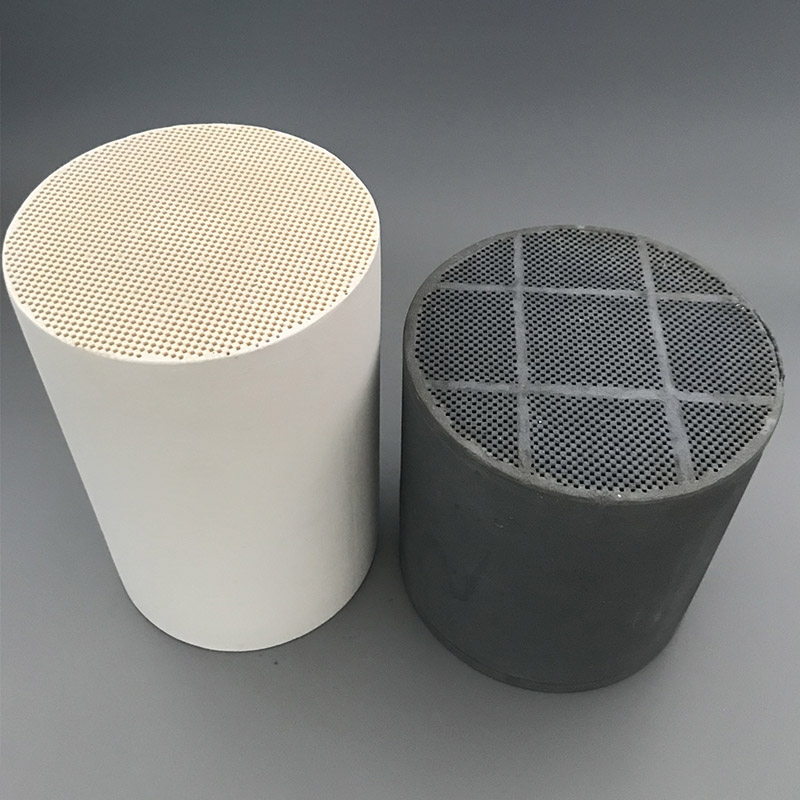

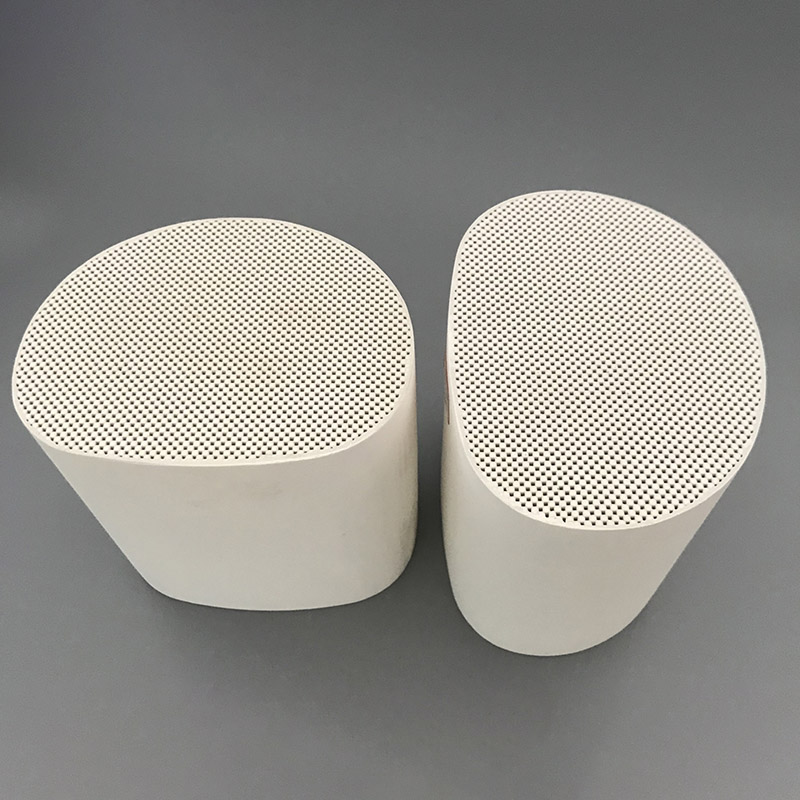

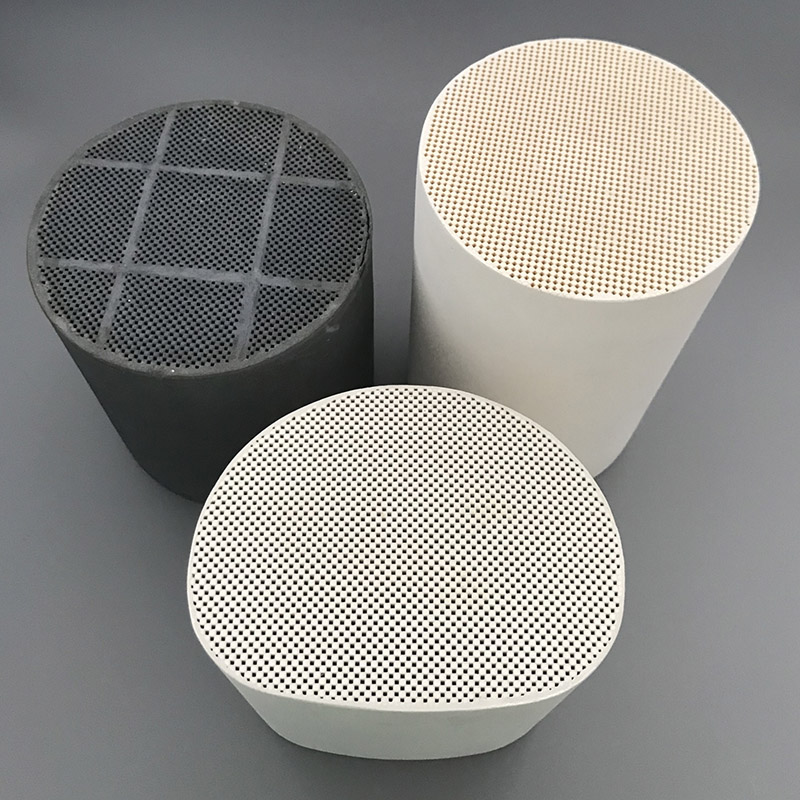

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for China Cheap Catalyst Substrate Ceramic Manufacturers - Universal diesel particulate filter Euro IV catalytic converter – Hualian , The product will supply to all over the world, such as: Cambodia , Kuwait , Wellington , Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.